Know More ... Grinding mill filling calculations YouTube Jan 25, 2016· Video embedded· Mill power calculation % filling and estimate the ball mill ball filling ...

Best way to determine the balltopowder ratio in. To really choose, I guess it depends on the material and your mill (vial, RPM, media, filling volume).

Best way to determine the balltopowder ratio in ballmilling? What is the best way to determine the balltopowder ... and your mill (vial, RPM, media, filling ...

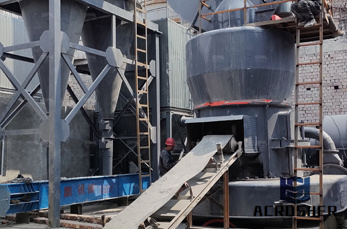

Ball mill is the main equipment of ore dressing process, and it is widely used in mining, metallurgy, building materials, refractory, cement, chemical and thermal ...

TECHNICAL NOTES 8 GRINDING R. P. King. 82 ... Figure Effect of mill filling on power draft for ball mills. ... steel balls in a ball mill, ...

calculation in filling ratio for ball mill Circulating load calculation in grinding circuits calculation in filling ratio for ball mill,Circulating load calculation ...

Ball Mill Filling Ratio, ball mill filling ratio (mill/grinding) equipment price. What is the standard media filling ratio for a ball mill Can you use ...

filling ratio in ball mill Iron ore dressing plant. What is standard media filling ratio for a ball mill Wiki Answers a)Idle running (without grinding operation ...

formula of ball mill volume. formula to calculate ball mill volume loading – Gold Ore Crusher. volume of ball mill calculations; ball load calculation in ball mills ...

Talk with the Experts at Paul O. Abbe about your process requirements and Ball Mill Loading, Wet Milling, Size Reduction needs.

effect of operational variables on ball milling Poli. Calculation In Filling Ratio For Ball Mill media and intermediate degree of both mil filling and percentage ...

grinding mill filling calculations. calculation in filling ratio for ball mill ball mill percentage filling calculations YouTube Aug 4, 2016, About iron ore ball ...

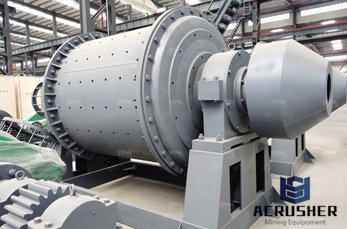

Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing, Ball mills rotate around a horizontal axis ...

Jan 25, 2016· Mill power calculation % filling and estimate the ball mill ball filling ratio of grinding mill calculation of ball filling ratio in grinding mill .

XSM Machinery (calculation of ball filling ratio in grinding mill) in mineral processing aspects widely used, many customers get more benefits, XSM product also ...

The optimal ball charge filling ratio for Combiball mills is supposed to be, One can calculate W m from the power draw of a mill measured at shaft P and the ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

STATISTICS Text Books calculation in filling ratio for ball mill,81 Definition 207 82 Components of Time Seri 208 83 Method of Least Square 217 84 Seasonal ...

Ball Mill SlideShare. Nov 18, 2008 ... Abstract The Ball mill is one of the most important equipment in the ... of balls charge ratio to the volume of mill is known ...

filling ratio in ball mill traydryercoin. Ball mill A typical type of fine grinder is the ball mill A slightly inclined or horizontal rotating cylinder is partially ...

Effects of slurry filling and mill speed on the net power draw of a, calculation in filling ratio for ball mill,11 Nov 2014, The Wits pilot mill (552 × 400 mm ...

ratio ''H/Di'' and using ... mill absorbed power and ball filling degree. As indicated on the graph, a small variation in power could be the result of a

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls ...

filling ratio in ball mill. Pictures of Taig Lathe Pictures of the Taig Lathe, Mill Other Tools and Accessories .

WhatsApp)

WhatsApp)