Crude Coal Tar is a by product of the Coking process. Coking is the process of heating coal in coke ovens to drive volatile matter from it.

73. ELECTRODE TESTS OF PURIFIED COKE FROM COAL IN ALUMINUM MANUFACTURE V. L. Bullough, L. 0. Daley, W. R. Johnson and C. J. McMinn

Processing. Metallurgical coal is used in the production and purification of metallurgical coke. It is during the heating process that the unstable components are ...

making process from coal to coke . Coke Production For Blast Furnace Ironmaking. Coke is the most important raw material fed into the blast furnace in terms of its ...

Calcination Wikipedia. The process of calcination derives its name from the Latin calcinare (to burn lime) ... decomposition of volatile matter contained in raw ...

The basic difference between coal and coke is that coal is the natural source and coke is the derivative product produced by destructive distillation. Both are used ...

Coke (fuel) Wikipedia, the free encyclopedia. Coke is a fuel with few impurities and a high carbon content, usually made from coal. It is the solid carbonaceous ...

Global steel production is dependent on coal. 60% of the steel produced today uses coal. ... displacing some of the coke required for the process.

Coal Preparation for Cokeoven Use The Coking Process of Coal in the Oven Chamber The Caking Mechanism of Coals ... Carbonization of coal, ...

Coal gasification is the process of producing syngas–a ... saccharin and many organic compounds are therefore derived from coal gas. Coke is used as a smokeless ...

Coal Mines and the Coking Process Coal and Coke Curriculum © 2008 Rivers of Steel National Heritage Area Page 1 Coal Mines and the Coking Process

What is coking coal? Quality coking coal, ... The coal is baked in a coke oven which forces out impurities to produce coke, which is almost pure carbon.

May 14, 2012· What is the difference between Coal and Coke? ... • Water content in coke goes t zero at the end of the coking process, but coal contains water. ...

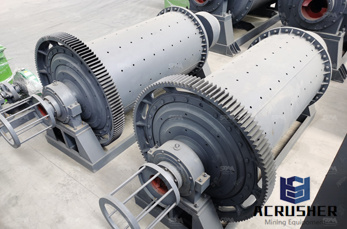

Processing Of Coal Into Coke, process crusher, mining . Processing Of Coal Into Coke 48 Views. The Zenith is the professional mining equipments manufacturer in the ...

Coal to Uploaded by Venkata ... can replace coking coal gMng coke with a ... wet charge process which relates coke strength indices to inert content of coal ...

The Coking Process Steel Heritage in ... explain how it is used to change coal into coke for use in steelmaking; create a drawing to illustrate the beehive

In the cokemaking process, bituminous coal ... Coke Manufacturing (grams per ton of coke produced, unless otherwise specified) Parameter Maximum value COD 100

Coke Production ... by the destructive distillation of coal in coke ... and 3 to give an overview of the process from coal preparation to ...

Petroleum Coke: Industry and Environmental Issues Congressional Research Service 3 Petcoke Compared to Metallurgical Coke and Coal Petcoke has a significantly high ...

History of Coke. Spraggers and ... describes the coke process: ... In 1980, the Indiana Coal and Coke Company was founded by Jacob and Paul Graff, ...

Coke is a material with high carbon content and porosity. It has high resistance to breakage and low reactivity with gases, particularly CO2. Coke production is an ...

Turning Coal into Coke. ... the facility will be the first domestic application of the Carbonyx Carbon Alloy Synthesis Process to create Cokonyx™.

Today in Energy. Glossary › FAQS › ... produces petroleum coke—a coallike ... of it is burned to provide the heat necessary for the cracking process. The ...

Metallurgical coal, also known as coking coal, is used to produce coke, the primary source of carbon used in steelmaking.

WhatsApp)

WhatsApp)